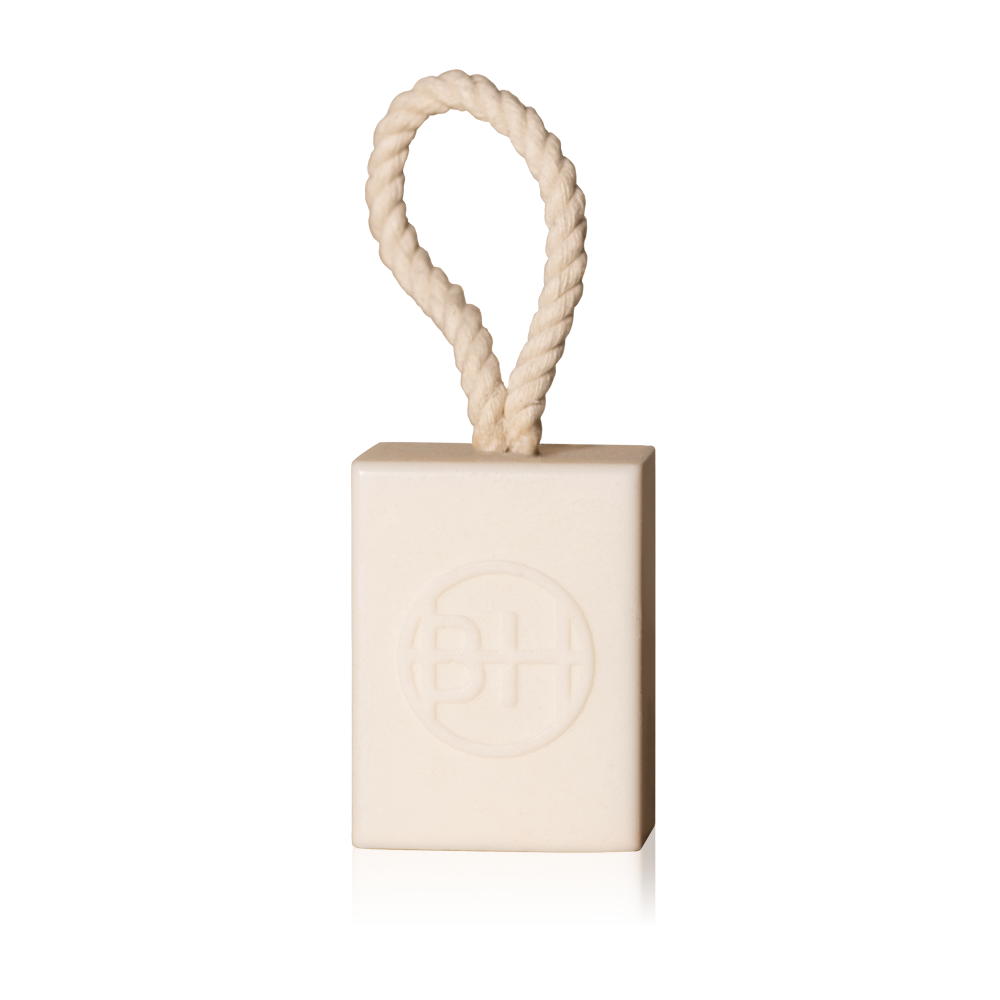

In our bustling making rooms at Dent, located near Sedbergh in Cumbria, I had the pleasure of conversing with Gareth Marshall, the production director and developer behind the recently launched innovative ‘soap on a rope’ body bars. With years of experience and a passion for quality, Gareth provided insights into the intricate process of crafting these modern soap bars as he walks us through the journey of bringing this concept to life in a contemporary context based on a timeless classic.

How did you find the mould maker?

Our pursuit of the perfect mould led us to a skilled artisan located just outside of Kendal, Cumbria. Richard and Roger Davenport, a father-and-son duo, operate a small workshop where they employ cutting-edge 3D printing technology to craft bespoke silicone and rubber moulds. Collaborating closely with them, we spent six months refining the design to ensure that it securely held the rope in place while maintaining the integrity of the soap.

Can you describe how you make them?

Crafting each body bar is a labour-intensive process that begins with precision and ends with finesse. First, we cut the hemp rope into uniform lengths and immerse them in a specially formulated soap mixture to bind the ends of the soap securely. The ropes are then carefully threaded through the mould, ensuring a snug fit without compromising the soap’s integrity. After pouring the liquid soap into each mould, we patiently wait for 24 hours for it to set. Once extracted, the soaps undergo a week-long curing process, during which they develop their final form. Hand-finishing ensures that each soap meets our exacting standards before being meticulously packaged.

Where is the rope from?

Our search for the ideal rope led us to a trusted manufacturer we’ve partnered with near Richmond in North Yorkshire. Through meticulous trials, we selected a natural hemp cotton rope renowned for its durability, quick-drying properties, and absence of unwanted odours. It’s was important to us to have quality that extends beyond the product itself to every component used in its creation. The hemp material also aligns with our sustainability ethos, the rope is fully compostable, making this product entirely plastic-free with minimal waste.

What particular ingredients did you use and why?

Our selection of ingredients reflects our commitment to both efficacy and sustainability. Opting for ingredients like Cocoa butter and Coconut oil not only imparts solidity to the soap but also provides moisturising benefits. Additionally, incorporating elements such as charcoal, allantoin and French Green clay enhances the soap’s cleansing properties while promoting skin health. Every ingredient serves a purpose, ensuring that our body bars not only perform exceptionally but also align with our values of environmental stewardship.

In our conversation, Gareth Marshall’s passion for innovation and dedication to quality shine through, underscoring Bath House’s commitment to crafting products that not only delight the senses but also nurture the body and soul. Through meticulous craftsmanship and a reverence for tradition, they’ve breathed new life into a cherished concept, ensuring its relevance in the modern era.